Perface

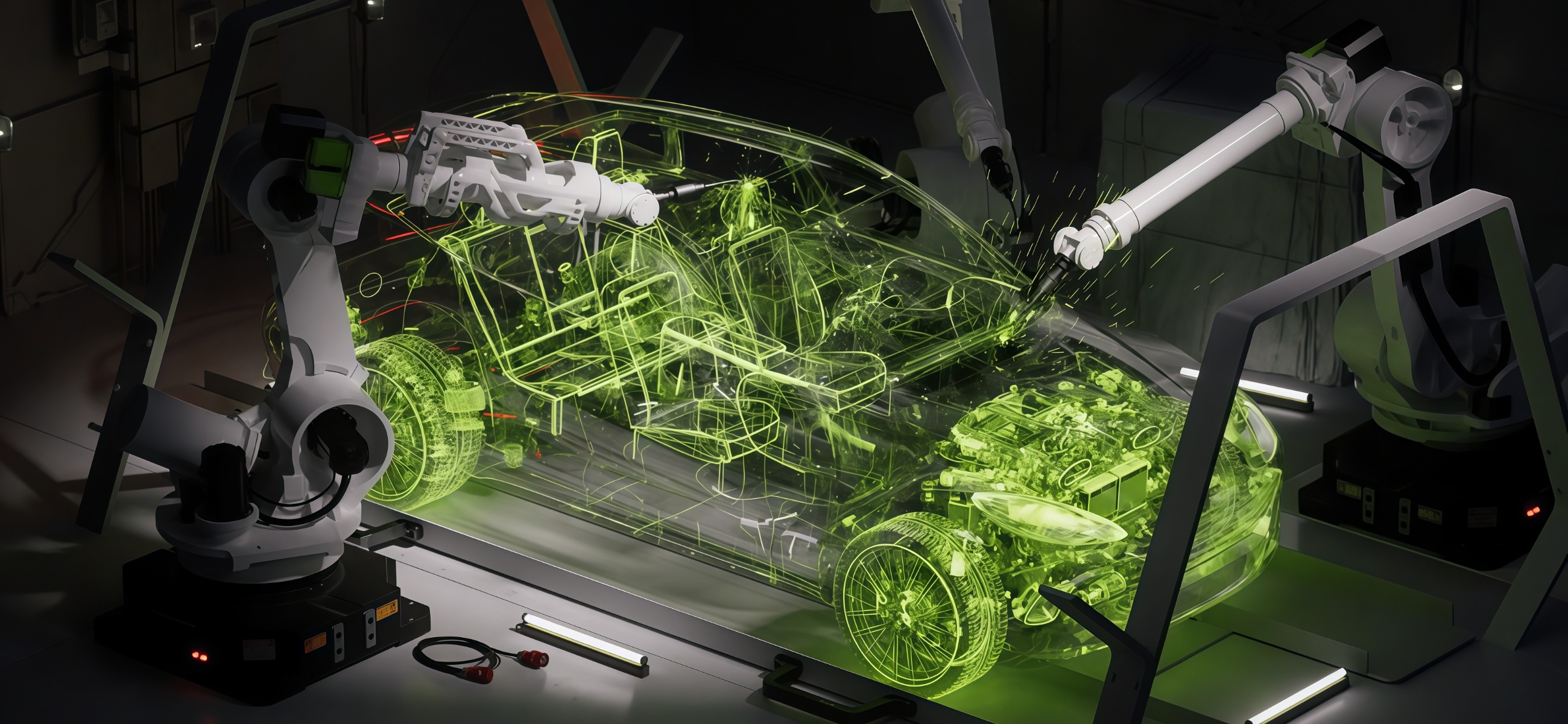

Ultra Light Process Technology Experimental Center was established in Beijing (Tongzhou). Function 1: Serve as the process R&D center for new machining technologies in key industries and specialized fields for Ultra Light, providing process services to clients. Function 2: Address the shortage of small-batch, high-precision, and customized machining resources in the market by delivering prototype manufacturing for clients. Function 3: Support the parts machining of prototype models for Ultra Light's self-developed products.

Background of Establishment

Background of Establishment

Against the backdrop of accelerating transformation and upgrading in the high-end manufacturing field, the mechanical processing industry is facing a significant supply-demand structural imbalance: traditional factory technology lags behind, high-end talent is lost, and talent reserves are cut off, resulting in a regional shortage of high-end processing capacity, making it difficult to undertake the small batch, high-precision, customized mechanical processing needs of numerous scientific research units and key areas of high-end industries. At the same time, many self-developed products of Ultra Light have entered the prototype testing and small batch trial production stage, and urgently need to solve the problem of small batch parts supply. Taking into account the market prospects and enterprise development, the establishment of Ultra Light Process Testing Center is not only a practical measure to solve the bottleneck of outsourcing and ensure the landing of products, but also a strategic choice to seize market opportunities and strengthen core competitiveness.

Order composition

Order composition

The order composition of this process testing center mainly consists of the following five points: firstly, the processing requirements for the parts used in the prototype of Ultra Light's new product, providing support for product research and development; The second is the transformation of component processes and tooling production for mass-produced products, bridging the gap between research and development and mass production; The third is the experimental verification and processing of machine tool products, which helps to iteratively optimize core technologies; The fourth is the sample making service for machine tool customers, providing decision-making basis for customers; The fifth is to undertake small batch, high value-added check-in and processing orders for relatively high-end industries such as aerospace, military, humanoid robots, medical equipment, etc., accurately filling the regional market gap.

From the perspective of the market environment, the supply gap of high-end regional processing capacity provides excellent market opportunities for enterprises. The establishment of Ultra Light Technology Testing Center can precisely focus on this niche market. With Ultra Light's technological advantages in the field of processing technology, it can fill the gap in this field, expand external high-end processing single piece and small batch orders while meeting its own production needs, and open up new profit growth points.

From the perspective of the long-term development strategy of the enterprise, the Process Testing Center will become a key carrier for Ultra Light to build a closed-loop system of "research and development production verification". The Process Testing Center not only undertakes part processing tasks, but also serves as a platform for process research and technological innovation. By continuously exploring high-precision machining technology, optimizing customized production processes, accumulating core process experience, and forming differentiated competitive advantages.

Conclusion

The establishment of Ultra Light Technology Testing Center not only conforms to the market development trend, but also provides support for product research and development, and consolidates the technological and production capacity foundation for the long-term development of the enterprise. In the future, Ultra Light Technology Testing Center will continue to deepen its cultivation in the field of mechanical processing, accelerate the research and development of process technology, improve service levels, and become a "process expert" around customers.

Message

Message