Recently, the pre acceptance work of the cylinder body machining project jointly operated by Ultra Light and Beijing Huade Hydraulic Industry Group Co., Ltd. (hereinafter referred to as "Huade Hydraulic") has been successfully completed. After comprehensive testing by the Huade Hydraulic Professional Acceptance Team, the performance indicators of the cylinder processing automatic production line designed and developed by Ultra Light have reached the preset standards and successfully passed the pre acceptance.

The successful acceptance of this project not only demonstrates the technical strength of Ultra Light, but also promotes further deepening of strategic cooperation between the two parties, and provides a model for intelligent processing of core components in the hydraulic industry.

Beijing Huade Hydraulic Industry Group Co., Ltd. is a key enterprise under Beijing Jingcheng Electromechanical Holdings Co., Ltd. and the vice chairman unit of China Hydraulic and Pneumatic Seal Industry Association. It was established in 1979. Its products and services cover high-pressure hydraulic valves, engineering multi way valves, plunger pumps/motors, hydraulic complete sets of equipment, and are widely used in professional fields such as aerospace, engineering machinery, petrochemicals, etc. Its products are distributed throughout the country and exported to all parts of the world.

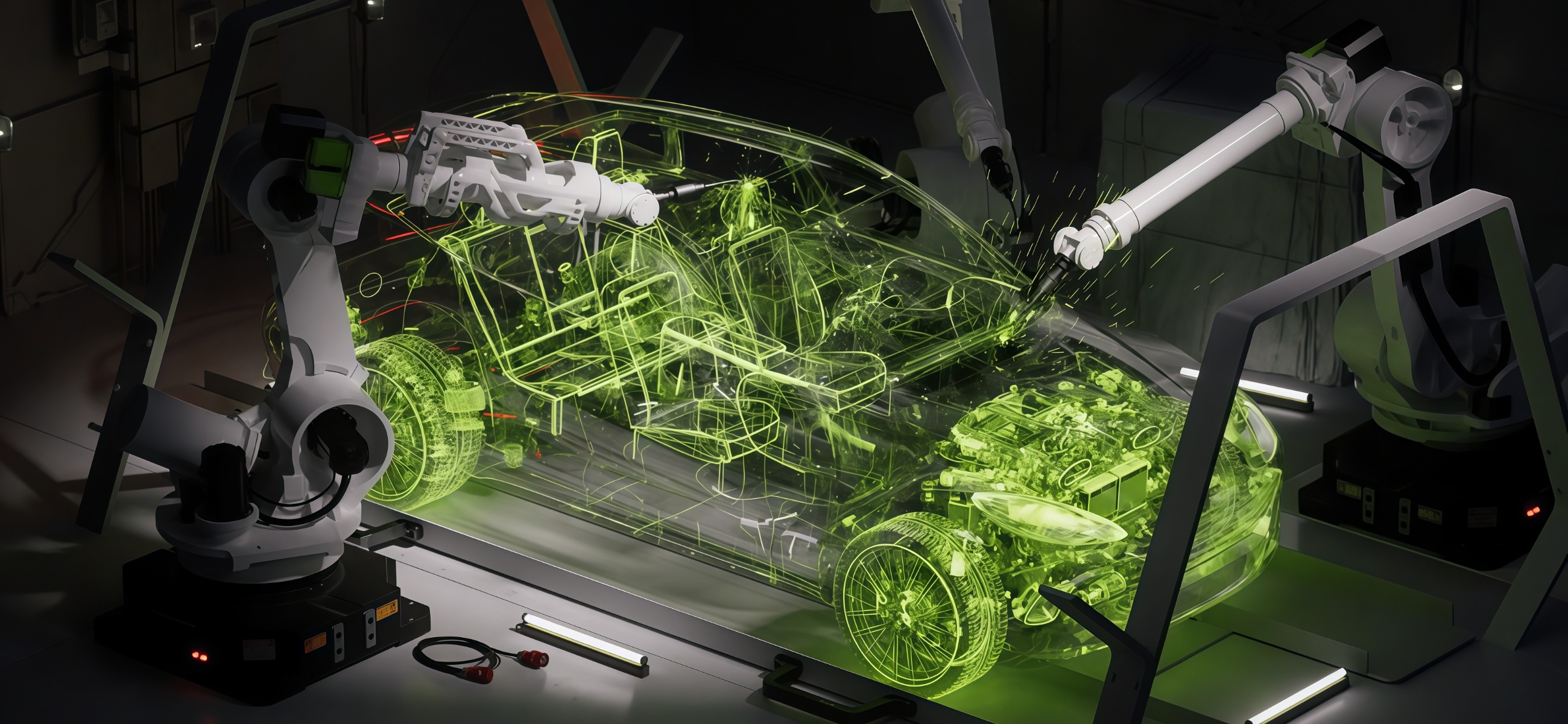

This project lasted for several months, from preliminary requirement research, mid-term scheme design, to successful equipment pre acceptance in the later stage. Each link was integrated with the 20 years of industry experience and technical accumulation of the Ultra Light team. It is precisely through our profound accumulation in the field of intelligent manufacturing that we are able to tailor an efficient and precise cylinder processing solution for Huade Hydraulic.

The more first-class enterprises require stricter standards. At the pre acceptance site, the Huade Hydraulic Acceptance Team conducted comprehensive testing around intelligent processing equipment. Testing will be conducted from aspects such as machining accuracy, equipment stability, and intelligent adaptation. In the process of precision inspection, the dimensional tolerance of the workpiece processed by the equipment is controlled within the specified range, meeting the processing requirements of Huade hydraulic workpiece products; In stability testing, the equipment operated continuously and smoothly without any malfunctions or shutdowns; In intelligent adaptation testing, the equipment can seamlessly integrate with the existing production management system of Huade Hydraulic, achieving digital control of order scheduling and process flow.

The successful completion of this pre acceptance fully reflects the technical strength of Ultra Light and is also the best recognition of Ultra Light's professional services. Next, Ultra Light will prepare for the final acceptance and ensure the smooth progress of the final acceptance.

In the future, Ultra Light will continue to focus on the processing needs of the manufacturing industry, driven by technological innovation, providing customized solutions for more industry customers, and helping China's intelligent manufacturing with value creation!

Message

Message