Manufacturing is the foundation of a country and the basis of a strong nation. The Decision of the Central Committee of the Communist Party of China on Further Comprehensively Deepening Reform and Promoting Chinese path to modernization, adopted at the Third Plenary Session of the 20th Central Committee of the Communist Party of China, clearly proposes to "promote high-end, intelligent and green development of manufacturing". Faced with the policy orientation of the new era, the coordinated transformation of traditional manufacturing industry towards digitization and greening has become a necessary path for the high-quality development of the industry.

As a backbone force in the field of intelligent manufacturing, Ultra Light has always taken technology research and development as its foothold, and industry collaboration as its link, actively helping manufacturing enterprises to embark on a "digitalization" and "greening" transformation path that combines ecological benefits and production efficiency.

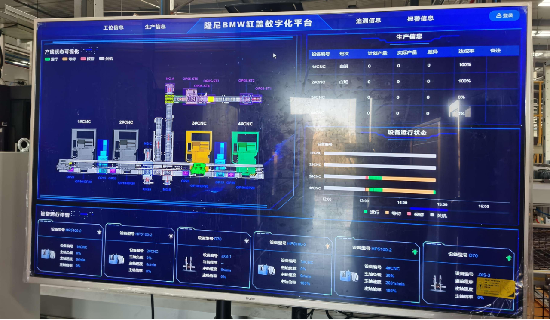

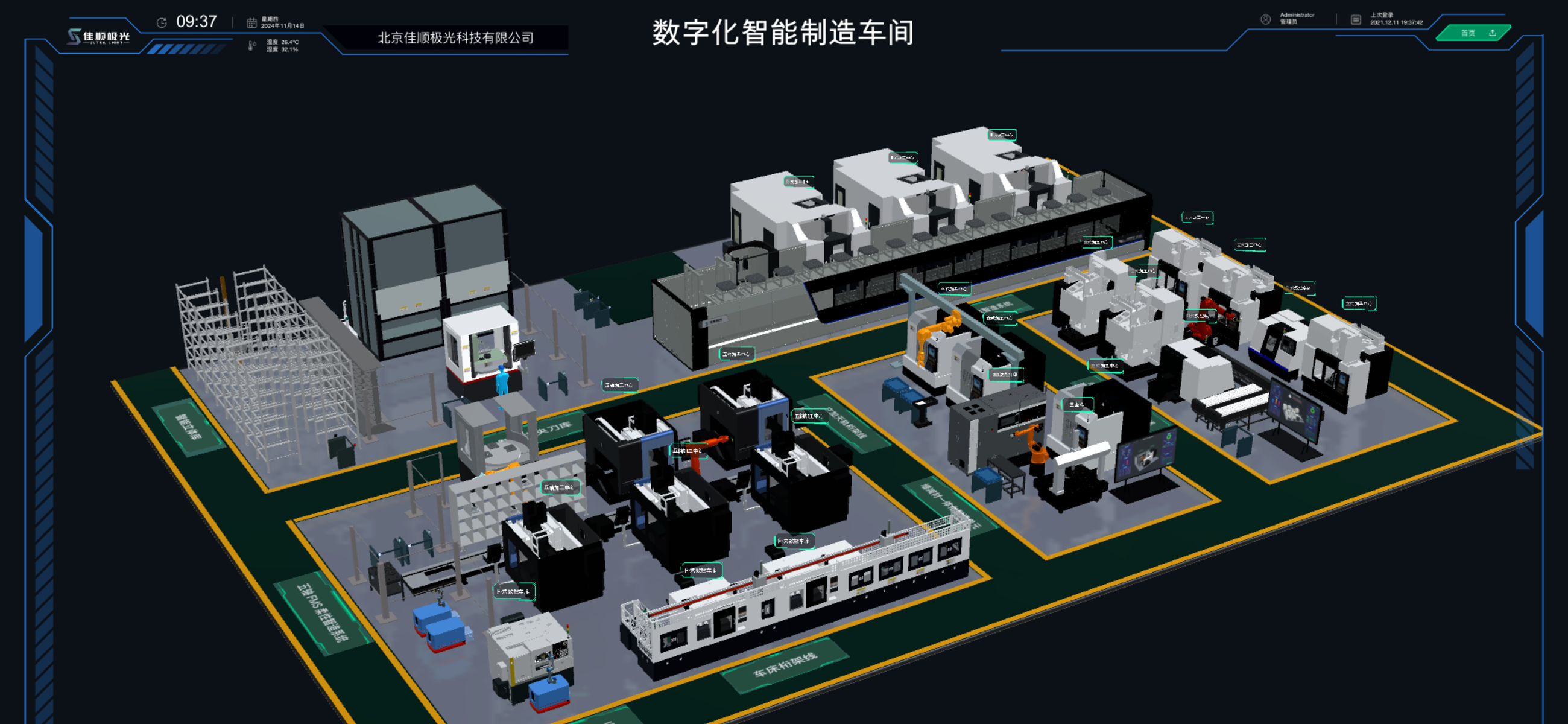

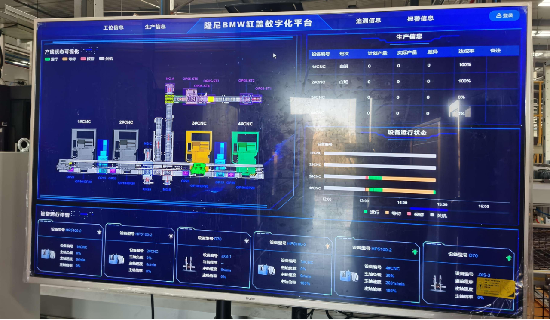

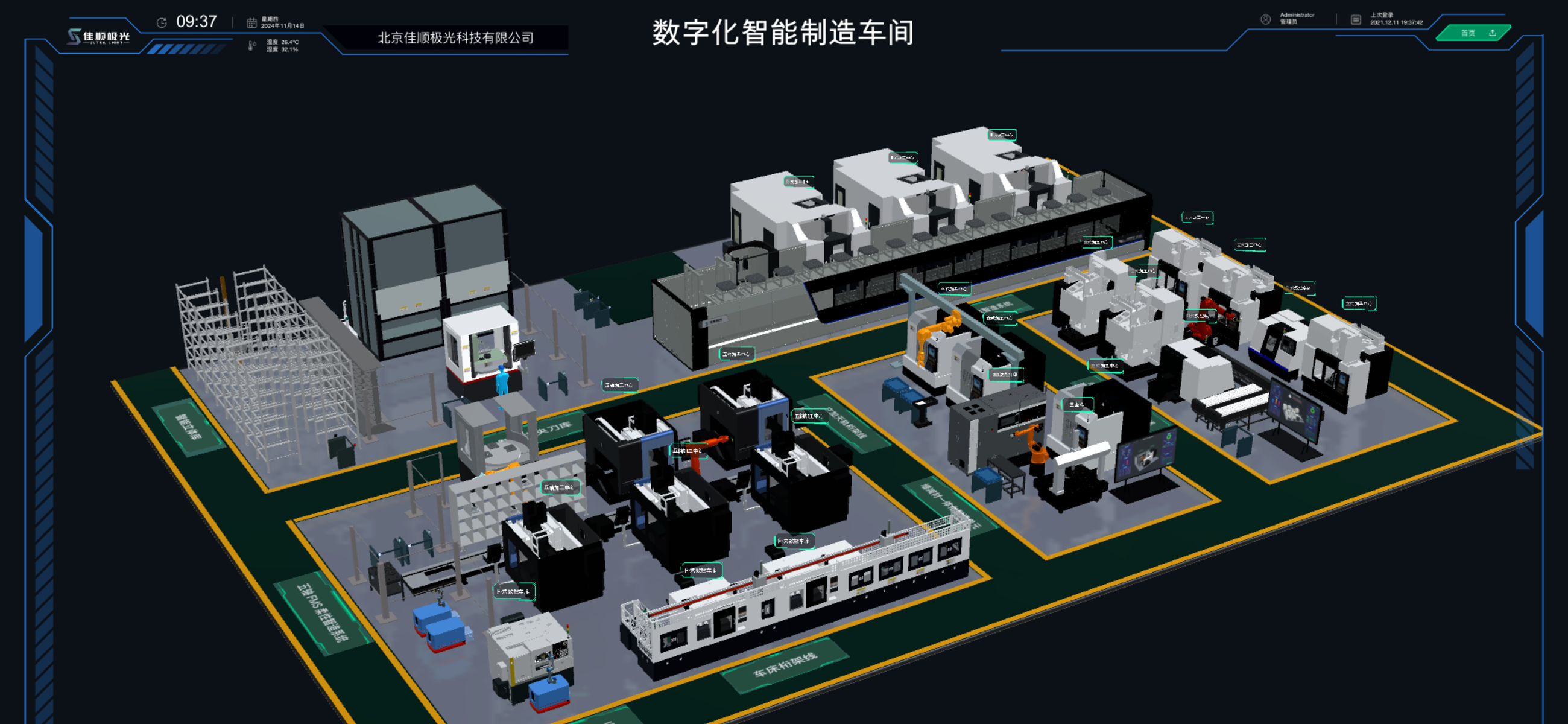

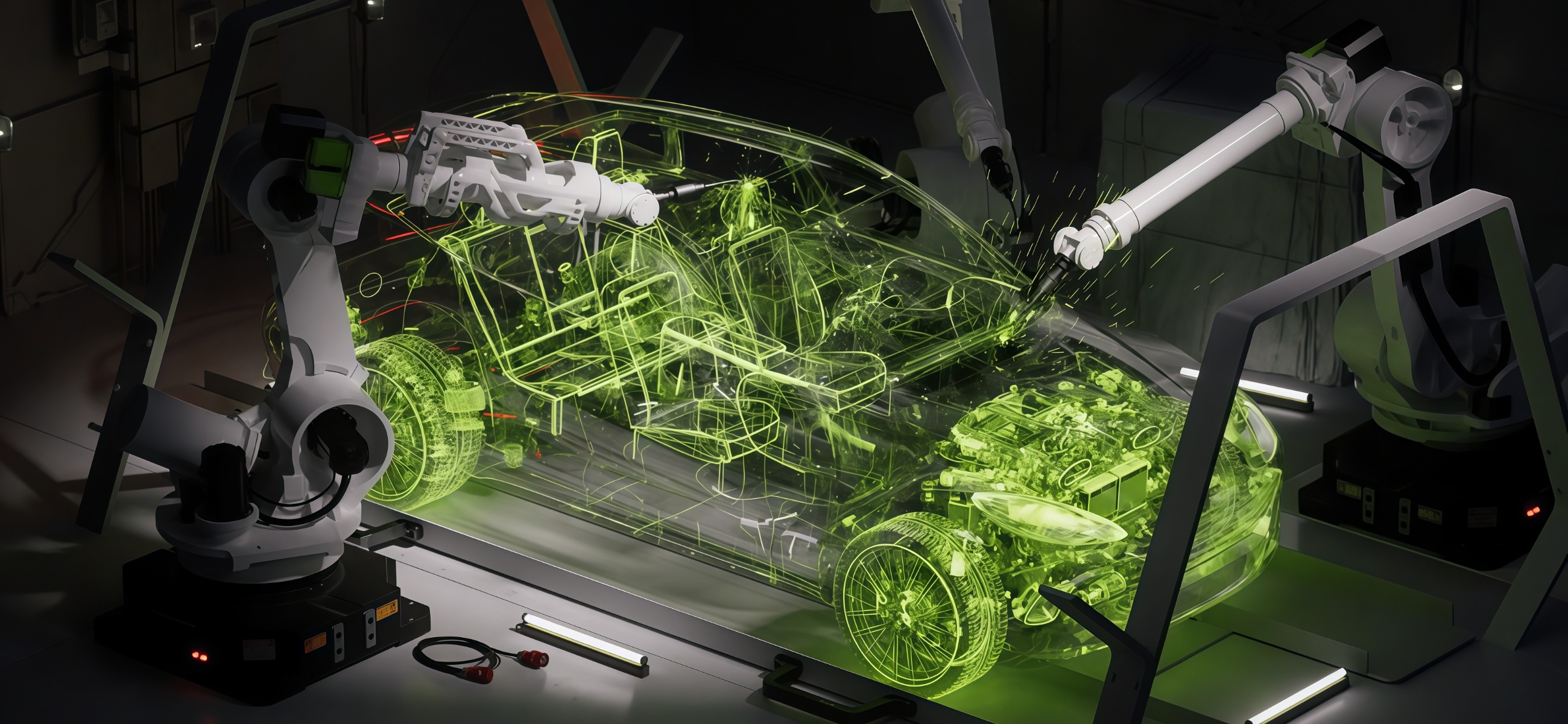

In terms of promoting the transformation of digital intelligence, Ultra Light focuses on data driven, breaking through the information barriers in the production process, reshaping the manufacturing process with the help of artificial intelligence, industrial Internet and other technologies, and creating a "smart brain" for traditional manufacturing enterprises. And delve into the actual scenarios of different industries, providing customized solutions for the production pain points of different industries. In addition, Ultra Light also uses digital twin technology to build virtual production lines, which can simulate the efficiency and energy consumption of different production plans before production, optimize processes in advance, avoid resource waste in traditional trial production stages, and truly achieve "improving efficiency with digital intelligence and reducing costs with intelligence".

Green transformation is also a key focus of Ultra Light's efforts. Ultra Light is deeply rooted in the field of intelligent manufacturing, and the core members of the team have nearly 20 years of industry experience. The enterprise has built various intelligent production lines for fields such as automotive, semiconductor, embodied robots, medical, and engineering machinery, organically combining advanced manufacturing processes with digital control to achieve precise scheduling of the entire production process. By monitoring the real-time operation status of the equipment, energy waste caused by machine idling is effectively eliminated; By intelligently matching material distribution and production pace, the resource consumption in the logistics process has also been significantly reduced. Not only that, Ultra Light also optimizes the production process through flexible manufacturing units, which not only meets industry requirements but also reduces raw material waste and optimizes energy allocation, achieving the dual goals of "efficient production+green and low-carbon".

Industrial collaboration is an important link in promoting the dual transformation of traditional manufacturing factories. Ultra Light not only focuses on its own technological development iteration, but also promotes transformation through school enterprise cooperation and industrial chain linkage. Not long ago, the company provided professional training equipment for Changchun Machinery Industry School and integrated the concepts of "digitalization" and "greening" into the talent training process, in order to reserve skilled talents for industrial transformation; Deep cooperation with leading enterprises in the machine tool industry, both parties have integrated intelligent and green design concepts into equipment research and development from the early stage, such as optimizing the energy consumption structure of machine tools, improving equipment compatibility to reduce duplicate investment, and then coordinating debugging during the later stage of production line landing, forming a green closed loop of "research and development production application". This model of "technology output+talent cultivation+industry collaboration" is a positive response to the policy's advocacy of "digitalization and greenization".

From national strategy to corporate practice, "digitalization" and "greenization" have become irreversible trends in the development of manufacturing industry. Ultra Light has broken through with technological innovation and empowered with industrial synergy, achieving synergistic progress in improving quality, efficiency, energy conservation and consumption reduction in multiple industry sectors. In the future, enterprises will continue to deepen technological integration and expand cooperation networks, injecting new momentum into the transformation and development of China's manufacturing industry.

Message

Message